All About Rosin

What is Rosin – How to Make Rosin – How to Smoke Rosin

Updated August 2022

Table of Contents

What is Rosin?

Rosin is a solventless cannabis extract that has become quite popular for being the cleanest and best form of concentrate currently available on the market. Rosin products are considered to be cleaner than BHO (butane hash oil) products like shatter, crumble, and diamonds because rosin does not require the use of any solvents, like butane used to make BHO. Rosin is produced with the use of heat, pressure, and filtration to squeeze the cannabinoids and terpenes from your starting material.

Benefits of Rosin

Producers love rosin because it is both safer and cheaper to make than most BHO products which require the use of expensive equipment and highly flammable gas. It can also be sold at higher price points relative to shatter. It is also an incredibly versatile product that can be made into any number of consistencies to fit unique purposes.

Consumers love rosin because of the flavor, potency, and purity. When producing rosin, the full-spectrum of cannabinoids and terpenes found in the cannabis flower that rosin starts as is extracted. Through the entourage effect, it has been shown that full-spectrum extracts are more beneficial than just single cannabinoid extractions.

Consumers also love rosin because you can safely and easily make it in the comfort of your own home. All you need is a source of heat and pressure like a rosin press or a hair straightener, cannabis flower or hash, a rosin bag, and some parchment paper. Check out the next section of this article to find out How to Make Rosin.

What Does Rosin Cost?

This can vary greatly depending on quality, location, and taxes. You might see grams of rosin for upwards of $100. You might also be able to get a gram from your local rosin-producer for $40.

What is Rosin? Solventless vs Solvent-free

Both of the terms “solventless” and “solvent-free” get tossed around pretty often, but what do they really mean and how are they different? Solventless means that the product was produced without the use of any solvents. Rosin and hash are both solventless.

Solvent-free means the end product does not contain any solvents. It does not mean the product was made without the use of solvents. Products like shatter, crumble, and diamonds are considered BHO (butane hash oil) products because they were made by using butane as a solvent. While shatter and other BHO products should not contain any solvent in the end product (solvent-free), they were made using solvents, so they are not solventless.

What is Rosin? Live Rosin vs Live Resin

Rosin is produced by adding heat and pressure to either flower or hash to squeeze out the extracted terpenes and cannabinoids. The term “live” in “live rosin” means the flower used to produce the rosin was frozen, not dried and cured, after cropping.

The term “live” in “live resin”, like “live rosin”, also means the flower that was used was frozen after cropping as opposed to drying and curing. Unlike rosin, live resin is produced using a hydrocarbon extraction, most commonly with butane.

So, live rosin is a solventless product. Live resin is a solvent-free BHO product.

What is WPFF?

Sometimes you will see rosin being described as “WPFF”. This stands for “whole plant fresh frozen”. It means that, after cropping, the whole cannabis plant was immediately frozen. No drying. No curing. No trimming. Many hash-makers enjoy WPFF material because it produces larger yields and a more full-spectrum product. Using WPFF material classifies the rosin made as “live rosin”.

How to Make Rosin

The Process

Producing rosin from either cannabis flower or hash does not require much. A source of heat and pressure like a rosin press or hair straightener, a rosin filter bag, some parchment paper, and your starting material are all you really need.

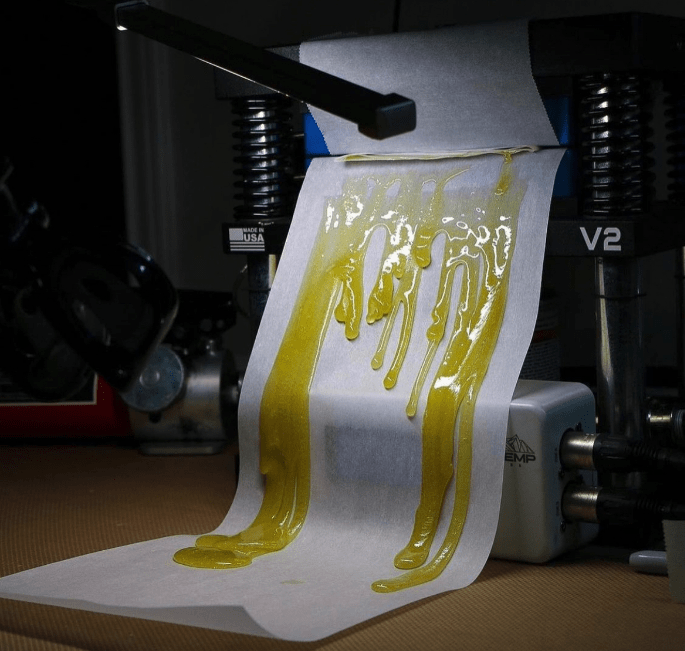

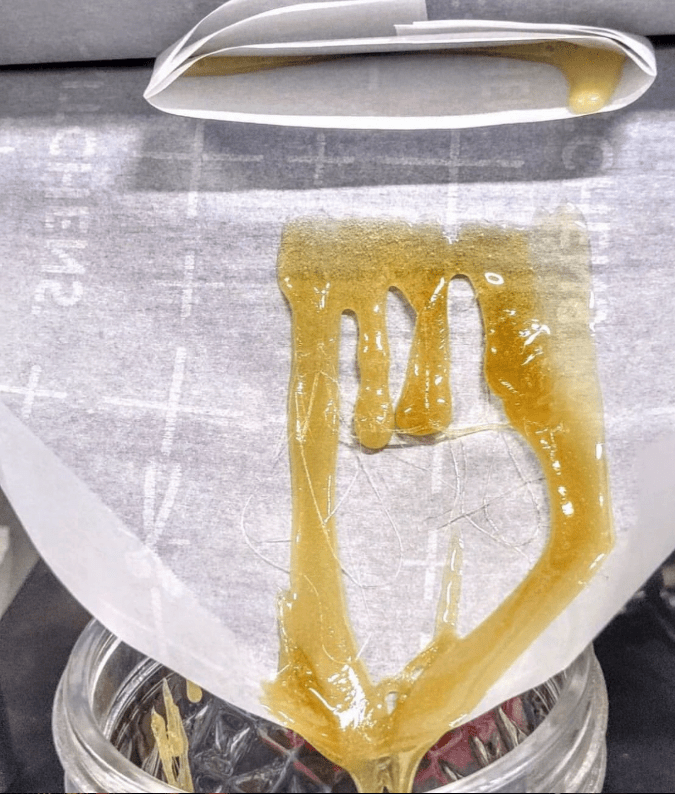

The rosin bag is filled with your starting material. Use your parchment paper to cover your rosin bag so when the rosin is squished out, it will collect on the parchment paper. Place the rosin bag and parchment onto the heated plates of either your rosin press or hair straightener. Then, squeeze! The rosin bag will hold in unwanted plant material while allowing the rosin to flow through the fine nylon mesh. Typically, the finer mesh (15µ – 50µ) is used to press hash rosin and the larger mesh (37µ – 220µ) is used for flower rosin.

Pressing Hash Rosin (Complete Guide Here)

You can preheat your press to about 180℉ to 210℉. Lower temperatures may produce a more badder-like consistency and need longer on the press to achieve full yield. Higher temperatures may result in either sauce-like or shatter-like consistencies. The most common temperature used is 190℉.

To press hash rosin, first, make sure the seams of your rosin bag are facing outward (flipped inside-out). Next, fill your rosin bag with the hash, starting with a nice base and working up. Be careful to avoid any air pockets and try to pack evenly. It can be helpful to form your hash into a brick then placing it into the rosin bag. Leave enough room at the top of the rosin bag to “close” it by folding it over. A quarter of an inch will do.

Line the plates of your rosin press with parchment paper to “catch” the rosin when it is squished out. It can be helpful to use magnets to keep the parchment in place. We suggest using a single piece of parchment that is folded in half to cover both the top and bottom plate. If you are producing larger quantities, you may consider using a directional fold.

Place your rosin bag into the center of the plates, then apply just enough pressure to hold it in place. Let it sit there for about 30 seconds or until the bag begins to “sweat”. This prepares the material to be pressed. Now, begin applying a steadily increasing pressure.

You should never really let the bag sit on the heat plates without applying more and more pressure. How long the press last depends on the temperature you use and the amount of material you are pressing. A good indicator of when the press is complete is along the edge of the press plate. You may see the rosin bubbling a bit as you press it out. When the bubbles stop, your press is most likely fully yielded.

Pressing Flower Rosin (Complete Guide Here)

You can preheat your press to about 180℉ to 210℉. Lower temperatures may produce a more badder-like consistency and need longer on the press to achieve full yield. Higher temperatures may result in either sauce-like or shatter-like consistencies. The most common temperature used is 190℉.

To press flower rosin, first, be sure that your flower is properly hydrated to about 62% relative humidity. If your flower is too dry, you can rehydrate it with hydration stones or some leafy greens like spinach placed into the bag for a few hours.make sure the seams of your rosin bag are facing outward (flipped inside-out).

Next, fill your rosin bag with the flower, starting with a nice base and working up. Be careful to avoid any air pockets and try to pack evenly.Use small-to medium sized buds with the stems removed. It is not best practice to use ground up buds. Leave enough room at the top of the rosin bag to “close” it by folding it over. A quarter of an inch will do.

Line the plates of your rosin press with parchment paper to “catch” the rosin when it is squished out. It can be helpful to use magnets to keep the parchment in place. We suggest using a single piece of parchment that is folded in half to cover both the top and bottom plate.

Place your rosin bag into the center of the plates, then apply just enough pressure to hold it in place. Let it sit there for about 30 seconds or until the bag begins to “sweat”. This prepares the material to be pressed. Now, begin applying a steadily increasing pressure. You should never really let the bag sit on the heat plates without applying more and more pressure.

How long the press last depends on the temperature you use and the amount of material you are pressing. A good indicator of when the press is complete is along the edge of the press plate. You may see the rosin bubbling a bit as you press it out. When the bubbles stop, your press is most likely fully yielded.

Types of Rosin Presses (Complete Guide Here)

People that are asking “what is rosin?” are also curious about rosin presses they need to start making it. There are several types of rosin presses you can purchase to produce rosin either commercially or at home. Manual presses are the most affordable, but also require the most labor to use. You will be hand cranking the press. This is a great option for people who press smaller quantities at home for personal use. If you are pressing larger amounts, you should consider either a hydraulic or pneumatic press. These presses can produce a lot more pressure than the manual presses. Some presses also come with digital interfaces so you can set and save preferences.

Hair Straightener Method (Complete Guide Here)

If you do not own or have access to a rosin press, you can use a hair straightener as your source of heat and pressure. This is really only suitable for pressing about 1 gram of flower at a time. You will not be able to produce enough pressure to fully yield a larger quantity. Follow the same steps described above in Pressing Flower Rosin.

Storage

Storage your rosin in an airtight glass container. Light, air, heat, and cold can all change your rosin’s consistency. It is best to keep your rosin in a dark place, preferably in the refrigerator to preserve the terpenes.

How Many Dabs of Rosin Will You Get From Pressing (Yield)

Your total yield from pressing flower or hash rosin is determined by your pressing process and how good the starting material is. Properly hydrated flower that was grown to have high levels of cannabinoids and terpenes will yield more than dried out flower that was not grown well. When pressing flower rosin, the best yields are about 30%. So a gram of flower can get you up to 0.3 grams of rosin. If you take regular sized dabs, this equates to around 5-10 dabs. When pressing hash rosin, you can see anywhere from 50% to 90% yield. Better hash and more practiced pressers produce higher yields.