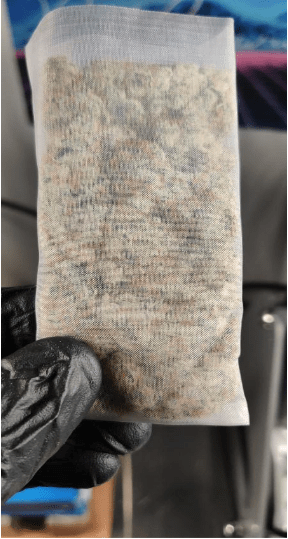

The Best Ways to Avoid Rosin Bag Blowouts and Bag Slips

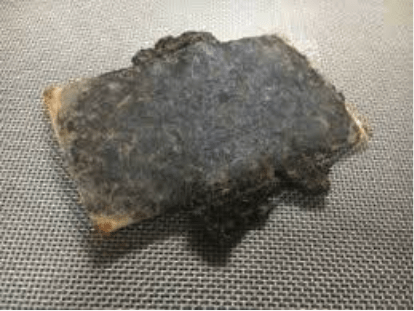

One of the biggest issues people face when pressing rosin is rosin bag blowouts. A blowout is when the rosin bag ruptures, contaminating the fresh rosin with unwanted plant material that is supposed to be held inside the rosin bag. This occurs when the rosin bag begins to slip out of place during a press.

It can be caused by a number of reasons ranging from the quality of your rosin bag to how you are applying pressure during the press. In this article we will cover ways to avoid rosin bag slips and blowouts, how to spot potential issues before they happen, and what to do if you do experience a blowout.

Table of Contents

How to Avoid Rosin Bag Blowouts and Bag Slips

Rosin Bag Quality

It should be no surprise that the quality of your rosin bags matter. Low quality bags are prone to both blowouts and bag slips. The nylon mesh of some rosin bags are held together with ultrasonic sealing, others are single or double stitched. Ultrasonic bags do not have seams and some believe this can help increase yields because no rosin gets stuck in seams.

It is also thought that these bags are less sturdy. Gutenberg’s Dank Pressing Co. rosin bags are double stitches to ensure strength. You will rarely, if ever, experience a blowout with these bags.

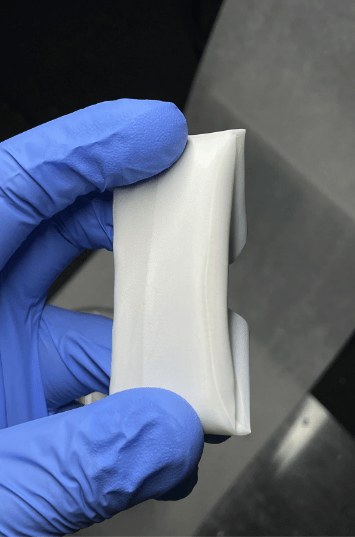

Overfilling

One of the most common causes of a rosin bag blowout is overfilling your rosin bag. This is a big no-no when filling rosin bags. You want to leave about ¼ to ½ inch of space at the top of your rosin bag. This can be used to fold over and “close” the bag. Each size bag can hold different quantities of flower or hash. For instance, 2×4 inch bags can fit about 7 grams of flower or 24 grams of hash while 4×7 inch bags can fit a whopping 24 grams of flower or 85 grams of hash.

Some pressers find that using multiple smaller bags is better than a single large bag. This way, you can be sure your bag is properly closed and there is less chance the bags will slip around and cause a blowout. It might be worth trying out something like two 2×4 inch bags rather than a single 4×7 inch bag.

Evenly Filled Rosin Bags

If your rosin bag is not evenly filled, chances are your bag will slip and eventually blowout. This goes for both flower and hash. Rosin bags that are evenly filled will have consistent pressure applied to the entire surface area of the bag. Uneven bags may have more pressure in one are than another, leading to a blowout. When pressing flower rosin, it is important to remove all stems. Break the buds into medium size nugs and evenly fill the bag (but don’t overfill it). For pressing hash rosin, it can be helpful to sift the hash into powder.

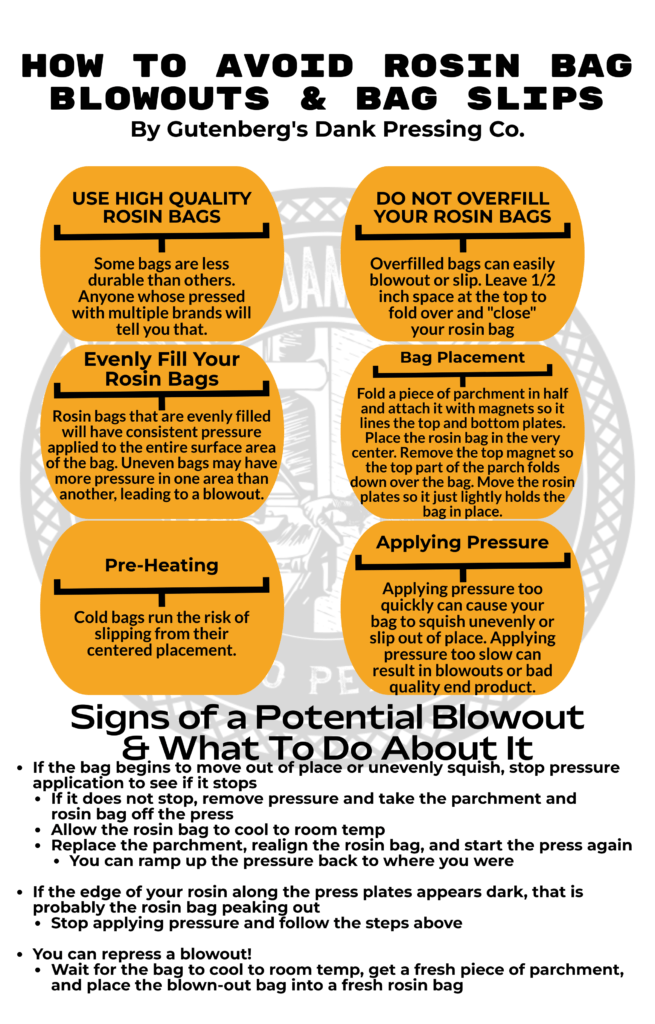

Leave about a ¼ to ½ inch space at the top of the bag. This flap can be used to fold over and “close” the rosin bag. Be very careful to avoid air pockets! These can be devastating. You may find it helpful to use a pre-press mold to form your bag into an even brick shape. The rosin bag should be a flat, evenly filled brick (unless you are pressing bottle tech or chottle tech style).

Bag Placement

The rosin bag(s) should be placed in the dead center of the rosin press plates (bullseye!). To accurately do this, first fold a piece of parchment paper in half. It should be long enough that it will reach to the back of the rosin plates and extend several inches past the front. Line the rosin press plates with this piece of parchment paper and lock the front ends of the paper in place with magnets on the press itself.

Next, place your rosin bag(s) onto the very center of the press. Now, let the top of the parchment paper loose so it lays onto the rosin bag(s). Apply some pressure to move the rosin press plates so that the bag(s) are lightly locked into place. It is important to not apply too much pressure here. Once the bag(s) are firmly in place, you can put the top of the parchment paper back up using the magnet. Double check that your rosin bag(s) are centered on the press plates before proceeding.

Preheating

Preheating your rosin bags before beginning to apply pressure is a critical step to a successful press. You want the rosin press to have just enough pressure to be holding the rosin bag(s) in place on the heated press plates. To be clear, there should be as close to 0 psi as possible. Let the bags sit on the heated plates for about 30 seconds or until you begin to see the bags “sweat”.

Preheating allows your starting material to warm up to optimal pressing temperatures before you begin to squish. This can increase both yields and quality. Without preheating, you run the risk of the bag slippage as the cold starting material is not as sticky as when heated.

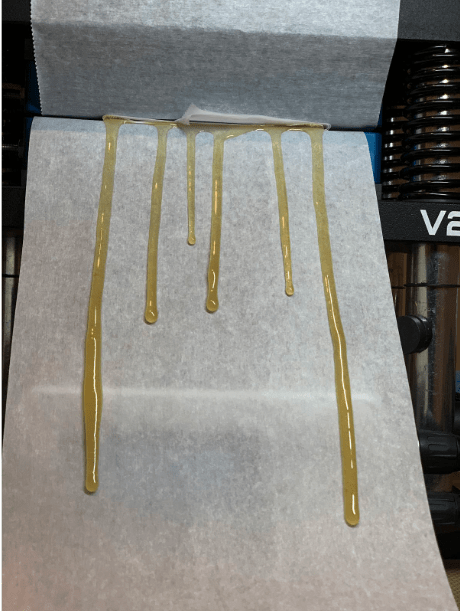

Pressure Build Up

Pressure applied too quickly can result in the rosin bag moving out of place on the press plates. Pressure applied not quick enough can cause the rosin bag to clog. Both situations can result in undesirable blowouts. That sweet spot right in the middle of too fast and not fast enough is where you want to be. Your touch for this will develop the more you press. As they say, practice makes perfect.

After preheating your rosin bag for about 30 seconds, begin to slowly apply a consistently increasing pressure. You should not let the bag sit for more than a couple seconds without increasing the pressure just a bit more. Consistently increasing pressure over the course of the press should help you to avoid any blowouts and bag slips. Once a decent amount of pressure is applied, the rosin bag should be locked into place.

Double Bagging

One popular technique to avoid blowouts is Double Bag Tech. As you may have guessed, double bag tech involves the use of two rosin bags wrapped around your starting material. This greatly increases strength so you can really pump up the pressure and increase yields without worry of a blowout. Having two bags instead of one may decrease yields, but some feel the amount is insignificant compared to the increased protection from ruining a press with a blowout.

This technique is reserved for pressing hash rosin, not flower rosin. To press hash rosin using double bag tech, first choose the bags you wish to use. Popular bag combinations are 25 icron inside a 120 or 160 micron, 25 micron inside another 25 micron, and 37 micron inside a 90 micron. Regardless of which bags you choose, the smaller micron should be the inside bag.

Pack your inner rosin bag as you usually would. Now, slide the bag inside your outer bag with the seams on the opposite side of the inner bag. Close the outer bag as you did the inner bag and viola, you are ready to go.

How to Spot Potential Rosin Bag Blowouts and Bag Slips

There are several signs you can look out for that might indicate bag slippage or blowouts are possible. For one, watch the bag at all times during the press. If you begin to see it move out of place, you may have to rescue that press. Pay attention to the shape of the bag, if you see one side begin to build up with more starting material, this could indicate a blowout is coming.

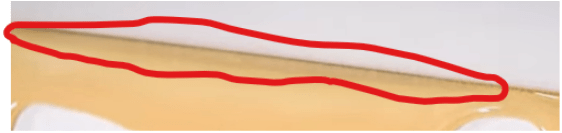

A major indicator of bag slippage is a darker color lining the edge of the rosin press plates. If you see darker colors than your rosin along the edge of the press plate, this is probably the rosin bag beginning to slip out of the press plates. If this is the case, you will need to rescue the bag before proceeding.

What To Do If You Have Rosin Bag Blowouts and Slips

Say you notice your rosin bag begin to slip, deform, or even blowout; do not panic! We can still salvage this press. First, remove the pressure from the rosin bag(s). Take the parchment with the rosin bag(s) off the press and let them cool to room temperature. Room temp rosin bags are MUCH EASIER to work with than bags that are still warm. Once cooled down, remove the rosin bag from the parchment paper. You can save this parchment paper to collect the rosin from it.

Next, if your bag DID NOT blowout, place the bag onto a new piece of parchment paper and then go through the pressing process again. In the beginning, you can ramp up the pressure to where you stopped before. This can save you some time.

If your rosin bag DID blowout, do not worry. You can repress a blowout! Place the blown-out rosin bag with the remaining starting material into a new rosin bag. Place this onto a new piece of parchment paper then proceed with the press as you usually would. You are most likely going to see a decrease in yield, but at least it is not a total loss.