Table of Contents

Rosin Basics

Rosin. . . . . yumm. Cannabis enthusiasts are turning to rosin because of its top-quality flavor, terpene profile, and because it is solvent-free. So what exactly is rosin? To make rosin out of cannabis flower or hash is to apply heat and pressure to the product, squishing out a full-spectrum (contains the entire chemical makeup of the plant) extract. This process, unlike other concentrates (shatter, diamond sauce, etc.) does not require the use of any potentially harmful solvents. The technique of making rosin has caught a lot of attention because it can be done at home with your own flower or hash and all without too much startup cost. Get your hands on a rosin press, some premium rosin bags, and some starting material and you are on your way to rosin-land!

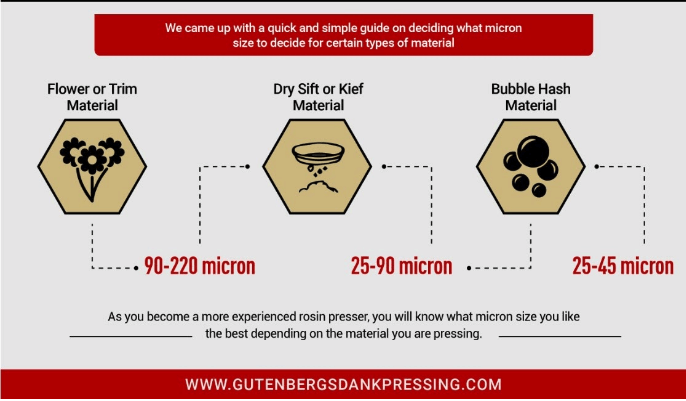

Rosin bags are nylon stitches mesh bags in varying “hole” sizes ranging from 25 microns (u) up to 220u. A micron is one millionth of a meter, so it’s really small. So small in fact that the bags, when pressed with the rosin press, hold in cannabis plant matter and let out the desired rosin extract. Several factors contribute to what ends up squishing out of the rosin bags. The amount of time being pressed, the temperature applied,the pressure applied, the size micron bag used, the starting material, and even the original strain all factor into the end product. How you use your rosin bags is entirely up to you. Practice and repetition will provide the knowledge and experience necessary for anyone to press their own quality rosin.

Typically, lower micron sizes work best for hash or kief presses and higher microns work with flower. For example, a dry sift press may utilise a 25u bag and an indoor flower press may use a 160u bag. Of course this is all up to the person behind the press. Some people use one bag inside another bag for added stability to avoid any blowouts (this is when the rosin bag develops a small tear as a result of exceeding pressure).

Temperature wise, flower tends to yield better at relatively higher temperatures around 200-225℉. Hash may do better at a lower temperature, around 160-180℉. The length of the press is really up to the presser. He or she can use visual cues from the rosin to tell when it is fully extracted. You want to avoid pressing so long that the material could burn and you want to press long enough that you yield as much extract as you can from the starting material. The amount of pressure applied is also up to the presser and usually is determined by a sense of feel. Developing this sense of feel and being able to see the visual cues comes with practice, practice, and more practice.

Experimenting with Flower Rosin

Although some general guidelines were laid out for which bags to use with which starting material, it really is a decision up to the person making the rosin. Any bag could be used for any starting product. Results constantly vary because of temperature, pressure, and starting material. So we reached out to our good friend, Michael, who runs the popular Instagram account, @dropnugznotnukes, to run a test of different micron bags starting with the same material and using the same temperature and pressing. Keeping the starting material, temperature, and pressure constant while only varying the micron size of the rosin bag used, we were able to develop a comparison of the end product based only on the rosin bag used. Let’s see how it turned out:

The Experiment

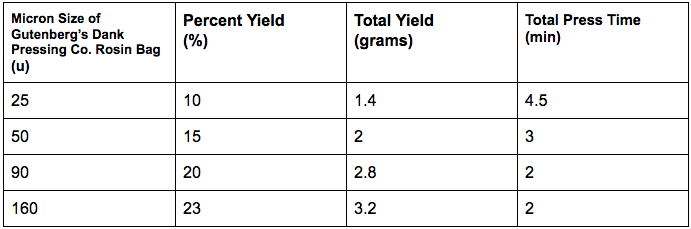

Each press started with 14 grams of Cherry Wine hemp flower. Testing showed the flower to contain 17% CBD, 1.59% CBG and 0.29% THC. The temperature was set to 185℉ for all the presses and the rosin press used was a 12 ton, home-built press. All the rosin bags had dimensions of 2×4 inches.

25u

Using Gutenberg’s Dank Pressing Co. 2×4 inch 25u rosin bags, Michael from @dropnugznotnukes shows us our first example of the give-and-take in decision making when making rosin. As with everything in life, to get something you got to give, the same goes for rosin. Using a lower micron size bag with flower yielded just 10% at 1.4grams. Additionally, the press took the longest amount of time at 4.5 minutes. Here is Michaels’s description of the end product:

“The Color Was By Far the Best, the Rosin was Silky Smooth and 100% free of ANY plant matter or Fats/Lipids! The Aroma Was Incredible”

Here a relationship between overall quality and yield is playing out. Although a low yield, the quality of the product is superb. It all depends what the presser is looking for.

50u

Next up, the Gutenberg 2×4 inch 50u rosin bags. The increased hole size in the nylon mesh bags will allow more material and larger material to pass through. As a result, the total yield and percent yield increased to 15% and 2 grams respectively. The press itself took less time than the 25u bags at just 3 minutes. Michael described the end product’s color as:

“ Incredible, Almost Zero Fatty Buildups”

Again we see the give-and-take of rosin pressing. As quantity increased, quality decreased. Time to press decreased as well.

90u

Squishing that Cherry Wine hemp flower using Gutenberg 2×4 inch 90u bags jumped the yield up to a solid 20% with a total yield of 2.8 grams. Quality wise, there were “noticeable fatty lipids”, the texture was very smooth, and the . . .

“ Aroma and color were amazing”

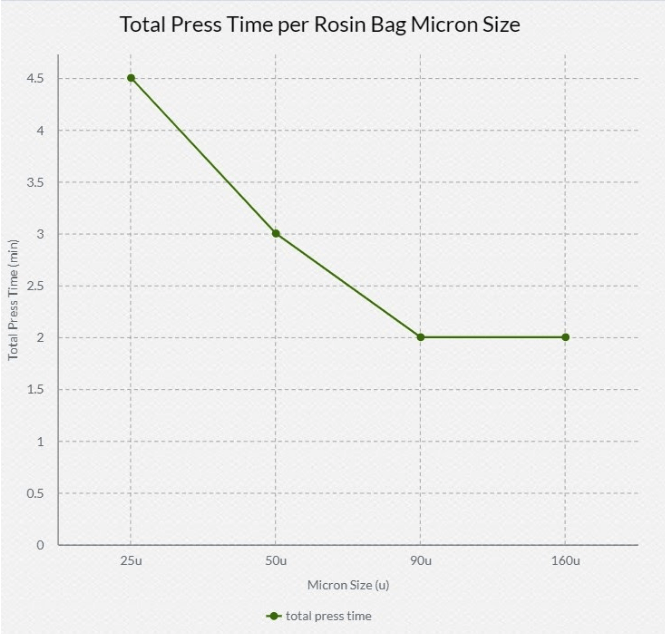

Following the inverse relationship between micron size and total press time, the 90u bags went for 2 minutes compared to 4.5 and 3 minutes using the 25u and 50u bags respectively.

160u

As expected from the pattern developing, using the Gutenberg 2×4 inch 160u bags increase the percent yield and total yield. A total of 3.2 grams were squished from 14 grams, or about a 23% return. The thick flow had noticeable lipids but the color remained eye-catching. The total press time did not follow the pattern of decreasing when micron increase and instead plateaued at 2 minutes.

“ I ran a 2 minute squish!”

. . . Michael had a lot of fun with this experiment 🙂

Review

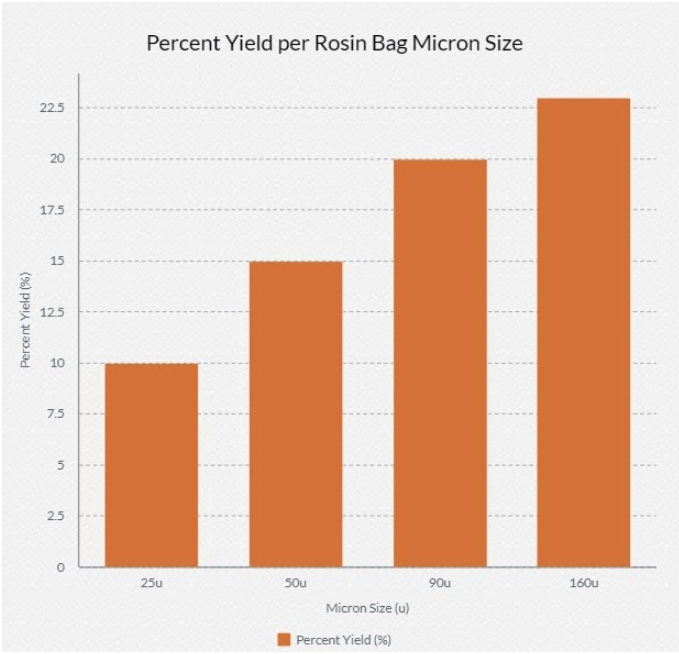

Percent Yield vs Micron Size: This graph displays the relationship between the percent yield of the press and the micron size of the Gutenberg’s Dank Pressing Co. rosin bag used when pressing 14 grams of hemp flower (Cherry Wine). As the micron size increases, so does the percent yield.

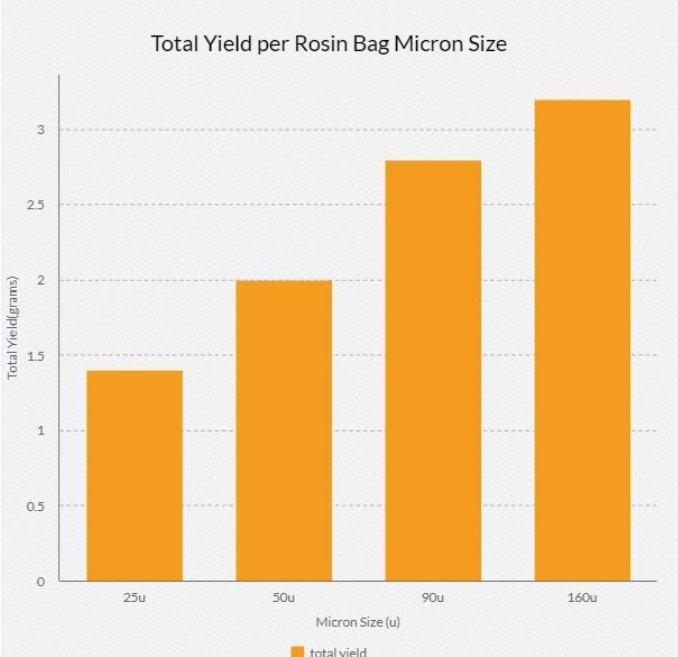

Total Yield vs Micron Size: This graph displays the relationship between the total yield of the press and the micron size of the Gutenberg’s Dank Pressing Co. rosin bag used when pressing 14 grams of hemp flower (Cherry Wine). As the micron size increases, so does the total yield.

Total Press Time vs Micron Size: This graph displays the inverse relationship between the total press of the press and the micron size of the Gutenberg’s Dank Pressing Co. rosin bag used when pressing 14 grams of hemp flower (Cherry Wine). As the micron size increases, the total press time decreases until it plateaus at 2 minutes.