SHOP ALL

Filter Options

2×9 Inch Rosin Press Bags 25 Packs

$21.99

Select options

This product has multiple variants. The options may be chosen on the product page

3×6 Inch Bottle Tech Style Rosin Press Bags

$10.99 – $18.99Price range: $10.99 through $18.99

Select options

This product has multiple variants. The options may be chosen on the product page

55 Gallon All Mesh Bubble Bags 4 Set

$349.99

Select options

This product has multiple variants. The options may be chosen on the product page

55 Gallon All Mesh Bubble Bags 5 Set

$399.99

Select options

This product has multiple variants. The options may be chosen on the product page

55 Gallon All Mesh Bubble Bags 8 Set

$495.99

Select options

This product has multiple variants. The options may be chosen on the product page

55 Gallon All Mesh Bubble Bag Single

$89.99

Select options

This product has multiple variants. The options may be chosen on the product page

2×4.5 Inch Rosin Press Bags 25-Pack

$21.99

Select options

This product has multiple variants. The options may be chosen on the product page

1 Gallon All Mesh Bubble Bags 8 Set

$37.99

Select options

This product has multiple variants. The options may be chosen on the product page

1 Gallon All Mesh Bubble Bags 5 Set

$30.99

Select options

This product has multiple variants. The options may be chosen on the product page

1 Gallon All Mesh Bubble Bags 4 Set

$27.99

Select options

This product has multiple variants. The options may be chosen on the product page

1 Gallon All Mesh Bubble Bag Single

$7.99

Select options

This product has multiple variants. The options may be chosen on the product page

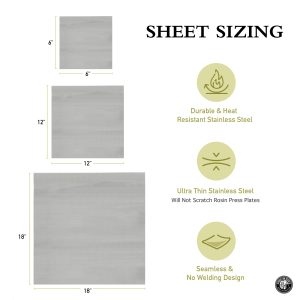

Stainless Steel Rosin Filter Screens

$15.99 – $222.99Price range: $15.99 through $222.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Bubble Bags V2 Cloth/Mesh Pick n Pack 4 Bag Set

$35.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Bubble Bags V2 Cloth/Mesh Pick n Pack 5 Bag Set

$40.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Bubble Bags V2 Cloth/Mesh Pick n Pack 8 Bag Set

$59.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon V2 Cloth/Mesh Bubble Bag Single

$10.99

Select options

This product has multiple variants. The options may be chosen on the product page

10 Gallon All Mesh Bubble Bags 4 Set

$99.99

Select options

This product has multiple variants. The options may be chosen on the product page

10 Gallon All Mesh Bubble Bags 5 Set

$129.99

Select options

This product has multiple variants. The options may be chosen on the product page

10 Gallon All Mesh Bubble Bags 8 Set

$149.99

Select options

This product has multiple variants. The options may be chosen on the product page

20 Gallon All Mesh Bubble Bags 4 Set

$128.99

Select options

This product has multiple variants. The options may be chosen on the product page

20 Gallon All Mesh Bubble Bags 5 Set

$159.99

Select options

This product has multiple variants. The options may be chosen on the product page

20 Gallon All Mesh Bubble Bags 8 Set

$177.99

Select options

This product has multiple variants. The options may be chosen on the product page

10 Gallon All Mesh Bubble Bag Single

$34.99

Select options

This product has multiple variants. The options may be chosen on the product page

20 Gallon All Mesh Bubble Bag Single

$39.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Cloth/Mesh Bubble Bag Single

$8.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon All Mesh Bubble Bag Single

$9.99

Select options

This product has multiple variants. The options may be chosen on the product page

32 Gallon All Mesh Bubble Bag Single

$44.99

Select options

This product has multiple variants. The options may be chosen on the product page

32 Gallon All Mesh Bubble Bags 8 Set

$247.99

Select options

This product has multiple variants. The options may be chosen on the product page

32 Gallon All Mesh Bubble Bags 5 Set

$199.99

Select options

This product has multiple variants. The options may be chosen on the product page

32 Gallon All Mesh Bubble Bags 4 Set

$174.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon All Mesh Bubble Bags 8 Set

$51.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon All Mesh Bubble Bags 5 Set

$34.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon All Mesh Bubble Bags 4 Set

$31.99

Select options

This product has multiple variants. The options may be chosen on the product page

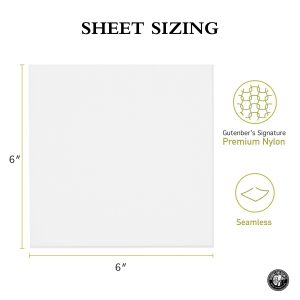

Rosin Micron Filter Sheets

$14.99 – $64.99Price range: $14.99 through $64.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rosin Filter Tube

$20.99 – $46.99Price range: $20.99 through $46.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon V1 Bubble Bags Cloth/Mesh Pick n Pack 8 Bag Set

$51.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Bubble Bags V1 Cloth/Mesh Pick n Pack 5 Bag Set

$35.99

Select options

This product has multiple variants. The options may be chosen on the product page

5 Gallon Bubble Bags V1 Cloth/Mesh Pick n Pack 4 Bag Set

$31.99

Select options

This product has multiple variants. The options may be chosen on the product page

2×4 Inch Bottle Tech Style Rosin Press Bags

$9.99 – $16.99Price range: $9.99 through $16.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

2.5×4 Inch Rosin Press Bags 25-Pack

$21.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

1.5×4 Inch Rosin Press Bags 25-Pack

$21.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

2.5×4.5 Inch Rosin Press Bags 25-Pack

$21.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

4×7 Inch Rosin Press Bags 25-50 Packs

$24.99 – $39.99Price range: $24.99 through $39.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

3×6 Inch Rosin Press Bags 25-50 Packs

$21.99 – $35.99Price range: $21.99 through $35.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5

2×4 Inch Rosin Press Bags 10-100 Packs

$9.99 – $50.99Price range: $9.99 through $50.99

Select options

This product has multiple variants. The options may be chosen on the product page

Rated 5.00 out of 5