Rosin Press Bags

Rosin Press Bags are used in the production of rosin products. The process of adding both heat and pressure to extract a concentrated version of your starting material is called “rosin”.

There are no dangerous and harmful solvents (like butane and propane) necessary in the production of rosin. Just heat and pressure along with some of the best rosin bags. This makes rosin the cream of the crop when it comes to concentrates.

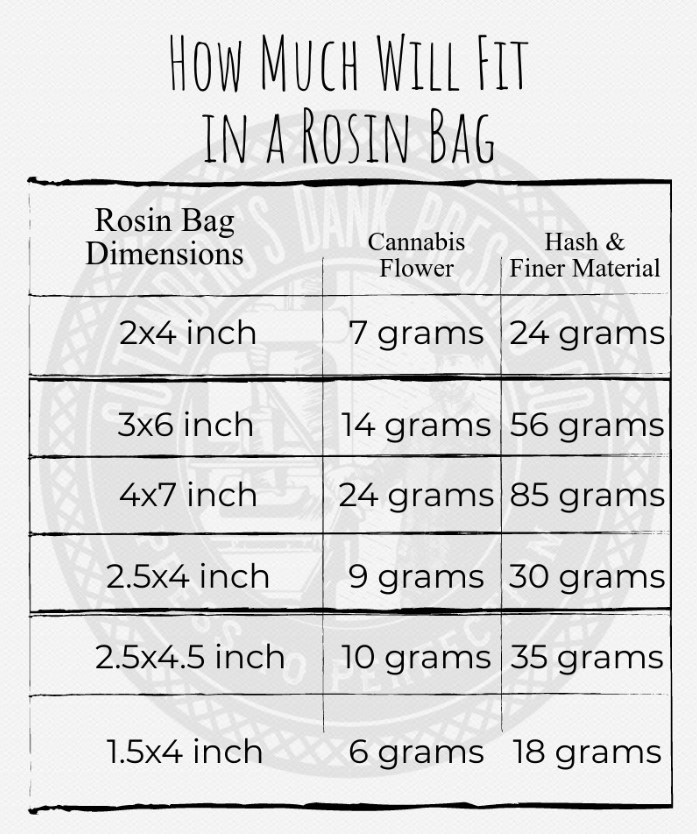

Scroll down ↓ to view all Rosin Press Bag Sizes.

Best Rosin Bags

In The Solventless Market

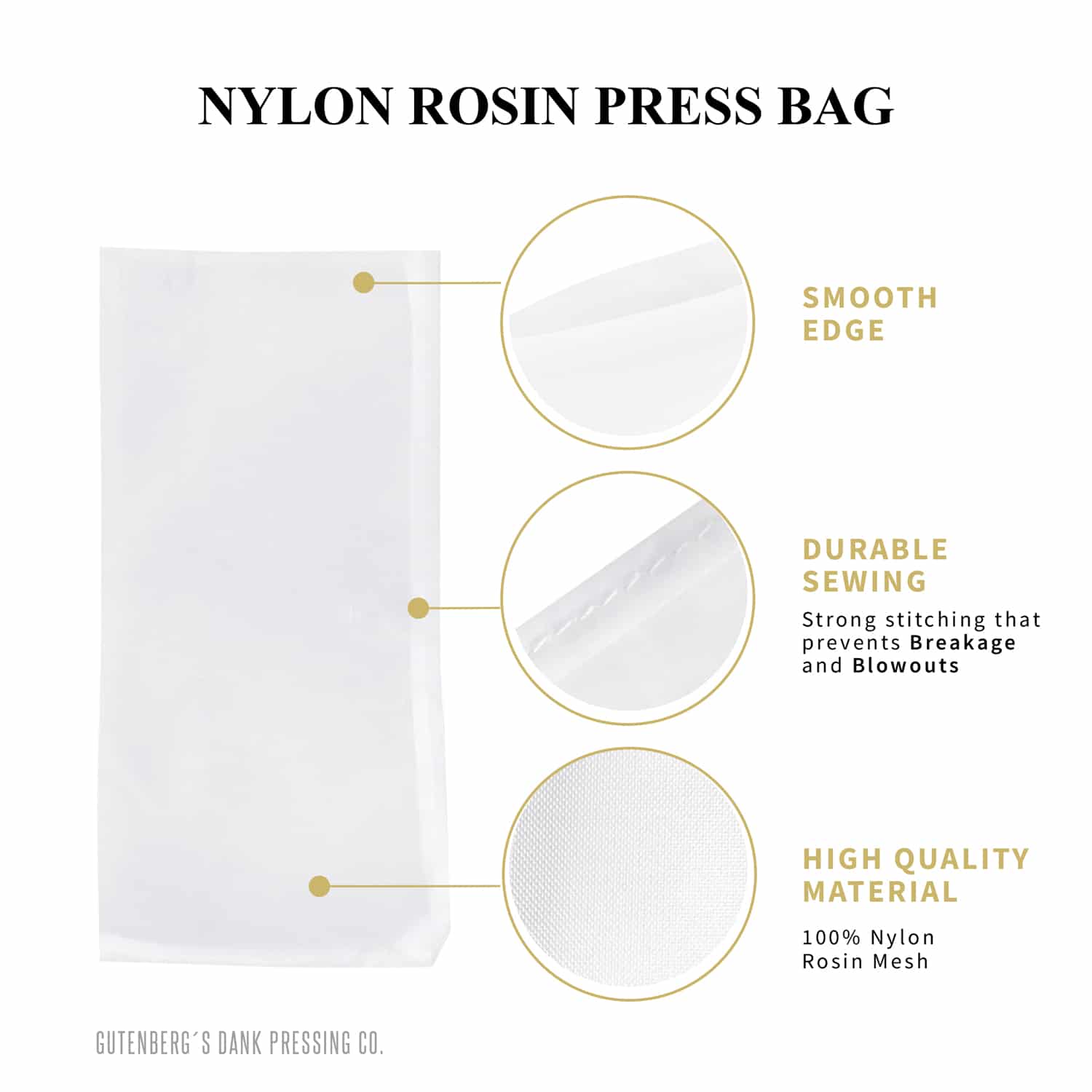

Bulk rosin bags are a crucial component of the rosin pressing process. Our premium rosin press bags are specially designed to hold cannabis or other plant material during the solventless extraction process. We use a our signature premium nylon material with our perfected double stitch sewing method that makes our products the highest durability and quality in the market. Bulk rosin bags are an ideal choice for large-scale commercial operations because they are available in larger quantities at a lower price per bag.

Choosing The Right Rosin Press Bag

The space between the fine nylon mesh that makes a rosin press bag is measured in microns. A micron (µ) is one-millionth of a meter. For scale, a piece of your hair is just about 20µ. Gutenberg’s Dank Pressing Co. offers the following micron size rosin press bags for sale: 15µ, 25µ, 37µ, 50µ, 75µ, 90µ, 120µ, 160µ, 190µ, and 220µ. The larger the micron size on the rosin bags, the more material will pass through the fine nylon mesh. This means higher yields, but may also mean lower quality as some unwanted material may pass through. Rosin bags with smaller micron sizes (15µ – 75µ) are generally used for finer starting material such as hash. The rosin bags with higher micron sizes (37µ – 220µ) are best used for larger starting material such as flower.

For hash, some users prefer to use 2-3 rosin press bags per press. The “Double Bag Tech” adds stability and durability to the rosin bag so the user can apply a high pressure without worry of a blowout. High pressure can mean high yields. Popular combinations for rosin bags include: 25µ inside a 25µ, 37µ inside a 90µ, 25µ inside a 160µ, and 25µ inside a 37µ. Which bag combination you use is entirely up to what works best for your process. We suggest using the smaller of the two micron sizes as the inside bag. Be sure to line the seams up as well!

Extra Info About The BEst Rosin Bags

For flower, users may choose to use Bottle Tech Style (BTS) Rosin Bags. These bags are stitched on opposing sides rather than the traditional side/bottom stitching.

When pressing BTS, the rosin bag is packed and placed on the rosin press so it squishes vertically rather than the traditional horizontal squish. The end result is a circular rosin puck. Some users feel that pressing BTS allows for better pressure control, higher yields, and reproducible results.

And remember, pressed rosin press bags (called rosin chips or pucks) can be saved up and used to make fun edibles or tinctures. Even after being pressed, these rosin pucks may still contain small amounts of cannabinoids. With a large amount of pucks, you can make edibles just as strong as if you used regular flower. Check out our guide here that can help get you started.